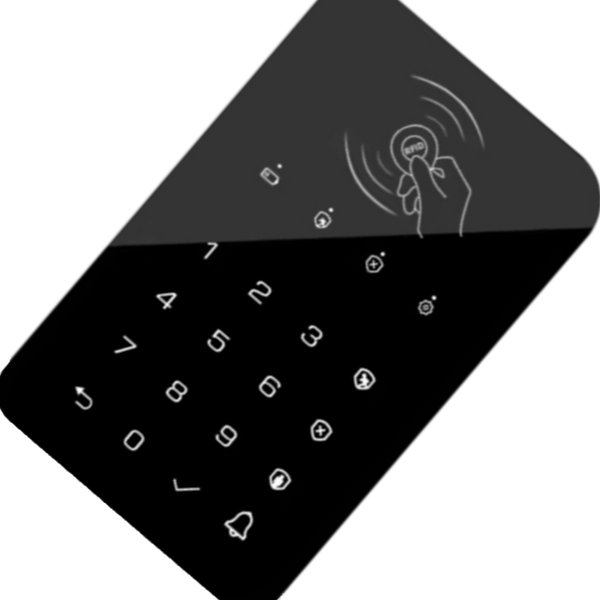

Capacitive keyboard

Capacitive keyboard

Capacitive keyboards guarantee a modern appearance and reliable operation at the same time. Capacitive sensors can be attached to the front panel by printing directly the sensors onto the substrate or by subsequent lamination. The panel can be made of glass, polycarbonate, plexiglass or other electrically non-conductive material. A completely waterproof, vandal-proof keyboard can be easily and cost-effectively designed with this technology. Capacitive keyboards can be partially or completely transparent, or can be illuminated.

The output signal of the keyboard is a capacitance change, which can be decoded with appropriate electronics.

General structures

One of the most common designs is that the design front panel and the capacitive sensor foil are laminated together.

Another common capacitive keyboard solution is to print the sensors directly to the design substrate (it can be glass, plexiglass, foil, etc.).

How does it work?

In an electrode solution, a capacitance change occurs between the electrode and the ground when we approach or touch the surface.

In a two-electrode solution, a capacitance change occurs between the two electrodes when we approach or touch the surface.

In both cases, the capacitive sensor electronics must detect the largest capacitance change (outside the limit value), thus excluding environmental effects, scatter, and other errors.

Related blogs

Capacitive Touch Sensitivity Calibration Guide for Different Foil Thicknesses - Complete Documentation

Technical Troubleshooting Guide for Capacitive Keyboard Electromagnetic Interference Issues

Understanding Adhesive Types for Membrane Keyboards and Overlay Foils: LSE vs HSE Surfaces and Surface Roughness

Why Choose Hungarian HMI (membrane keyboards, overlays, etc.) Manufacturing for Your Custom Solutions

Illuminating Innovation: Advanced Backlight Solutions for Membrane Keyboards

Why Antimicrobial Surface Overlays Are Essential for Medical Membrane Keyboards